Completion Equipment Qualification

Comprehensive testing for downhole tool performance

We perform comprehensive testing of completion equipment for the oil and gas industry, ensuring tools meet the highest performance and safety standards. Our testing capabilities include qualification of packers, safety valves, sliding sleeves, subs, and other downhole completion components. We test in accordance with API and ISO specifications, as well as customer-defined requirements, to ensure full compliance, operational reliability, and field readiness.

-

Downhole completion tools operate in extreme environments where failure isn't an option. Proper qualification testing ensures:

Tool performance under combined mechanical and pressure loads

Seal integrity at operating pressures and temperatures

Compliance with API and ISO specifications

Reliable field performance and operational safety

-

Our completion equipment qualification serves critical downhole operations:

Packer qualification for wellbore isolation and zonal control

Safety valve testing for well control and production safety

Sliding sleeve validation for flow control and selective production

Sub and connector testing for mechanical integrity and sealing

Custom completion tool development for specialized applications

-

Complete project management from start to finish:

Equipment Procurement: Source and coordinate delivery

Receiving Inspection: Dimensional verification and documentation

Functional Testing: Mechanism validation and operation verification

Pressure Testing: Internal, external, and differential pressure performance

Temperature Cycling: Performance under thermal conditions

Load Testing: Tension, compression, and combined load scenarios

Seal Integrity Testing: Validate sealing performance across operating envelope

Final Reporting: Comprehensive test documentation and analysis

Accounting: Complete project accounting

-

Comprehensive Validation Under Realistic Downhole Conditions

We test completion equipment using multiple parameters simultaneously—mechanical loads, pressure, and temperature—to simulate actual wellbore conditions.

Six load frames from 1.5 to 5 million pounds

Internal pressure up to 50,000 psi (liquid), 40,000 psi (gas)

External pressure up to 40,000 psi

Temperature testing up to 1200°F/650°C and down to -112°F/-80°C

Flow testing capabilities up to 10 barrels per minute at 4,000 psi

-

API Standards - Complete compliance testing for industry requirements

ISO Standards - Full standard requirements for international markets

Customer Specifications - Tailored testing to meet your unique requirements

International Regulatory Requirements - Documentation for global operations

-

We serve completion equipment manufacturers and operators worldwide:

Remote monitoring for global participation without travel requirements

Documentation meeting international standards and regulatory requirements

Flexible scheduling accommodating global projects and time zones

Technical support and consultation regardless of location

We handle every aspect of your completion qualification project—from start to finish.

Our fully managed completion qualification services coordinate all aspects of completion equipment testing while keeping you informed throughout the process.

PHASE 1

Component preparation

Equipment Procurement: Source and verify completion tools

Fixture Design: Create specialized test fixtures for your tools

Pre-Test Inspection: Document baseline conditions and specifications

PHASE 2

Performance testing

Pressure Testing: Validate sealing performance under operating conditions

Combined Load Testing: Apply realistic downhole stresses simultaneously

Functional Testing: Verify tool operation and performance parameters

PHASE 3

Documentation & delivery

Final Reporting: Comprehensive documentation with test data

Certification Support: Documentation for regulatory compliance

International Support: Remote monitoring for global participation

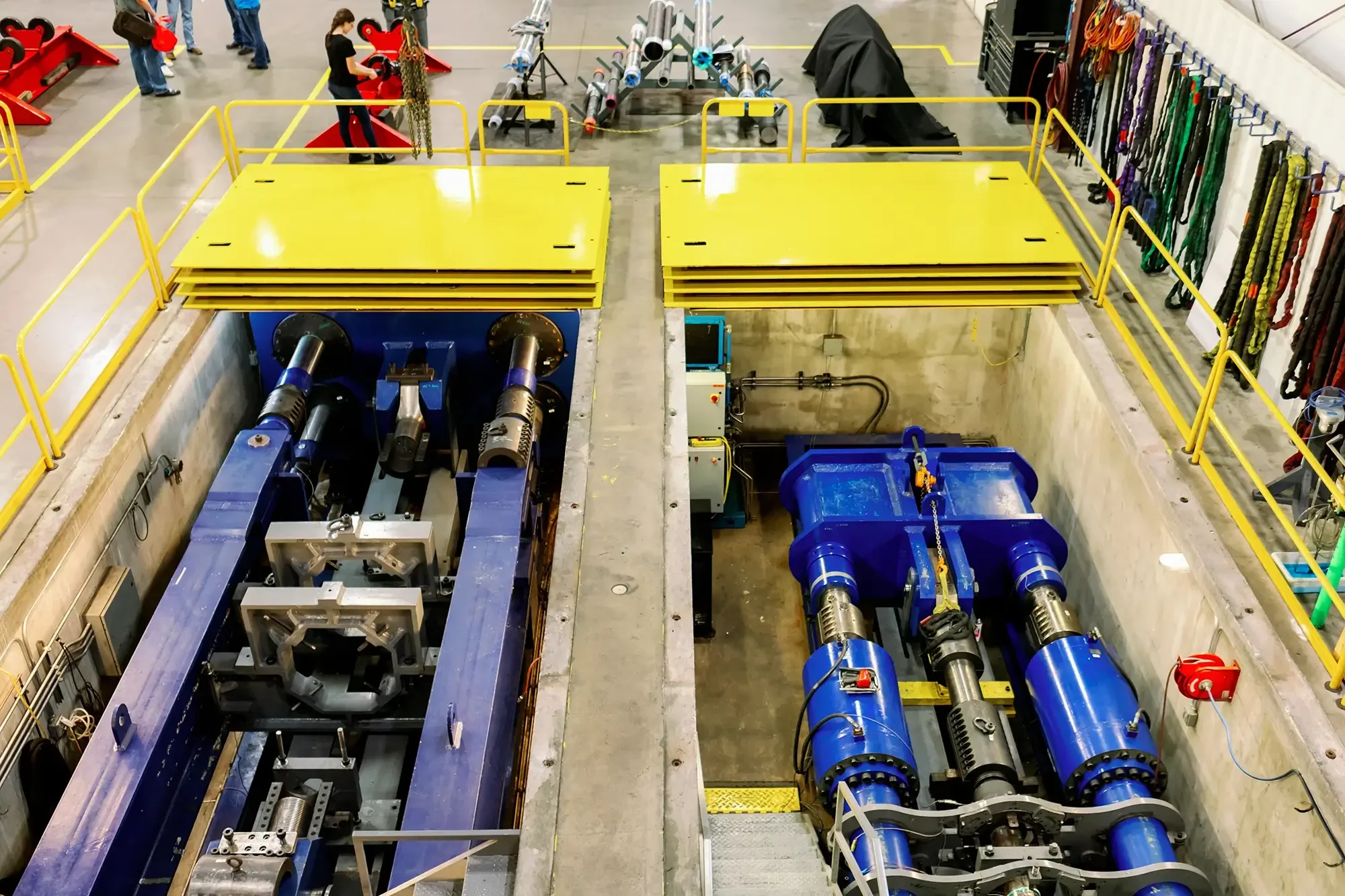

Combined Load Testing

Multi-parameter testing applying tension, compression, bending, pressure, and temperature simultaneously for realistic downhole conditions.

Custom Testing Programs

Tailored solutions designed specifically for your unique completion tool requirements, whether developing new tools, validating performance, or need specialized qualification testing.

Extreme Pressure & Temperature Cycling

Advanced HPHT and thermal cycling for the most demanding applications, including Series B testing and thermal shock validation.

High-Pressure High Temperature (HPHT)

Testing up to 60,000 psi and 1200°F through our advanced 10 and 4 Channel Systems for extreme environment applications.

Load Frame Capabilities

Six advanced load frames ranging from 1.5 to 5 million pounds capacity with full pressure and temperature integration for versatile testing configurations.

Load Testing

Comprehensive tension, compression, bending, and pressure testing to verify your completion equipment's performance under demanding downhole conditions.

Remote Monitoring

Real-time global access to testing operations with secure live streaming of images and data from anywhere in the world, enabling complete oversight without travel.

Patented Control Software & Automation

Advanced automated sequential testing with high-speed data acquisition and intelligent load control for precise results.

Strain Gage Services

Advanced strain measurement with over 3,000 strain gages applied annually. Uniaxial, biaxial, and triaxial configurations available for complete stress analysis of completion tools.

Torque Testing

Make and break testing up to 150,000 foot-pounds capacity for vertical and horizontal configurations, evaluating connection performance.

10 and 4 Channel System

Advanced multi-channel testing control for High Pressure High Temperature (HPHT) operations, enabling precise coordination of multiple testing parameters with automated cycling capabilities.

Ready to qualify your completion equipment?

Contact our team to discuss your completion equipment qualification requirements:

Call us: 1 (936) 931-0179 | Email us: sales@testing.net